The gas purification equipment is used for further deoxygenation and drying of the product gas generated. The purification equipment is especially suitable for heat treatment processes that need high purity nitrogen and hydrogen to increase the brightness of the final products. Our gas purification equipment is usually used together with PSA nitrogen generator. The equipment specifications can be customized according to the usage cases and generation equipment purchased to better support your production.

It is needed when producing nitrogen with a high purity up to 99.9995%

- Flow rate: 100Nm³/h-3000Nm³/h

- Nitrogen purity: O2≤5ppm

- Adopt compact structure design

- Low operation cost and easy operation

- It can also be designed into hydrogenation or carbon deoxygenation purification equipment according to special requirements.

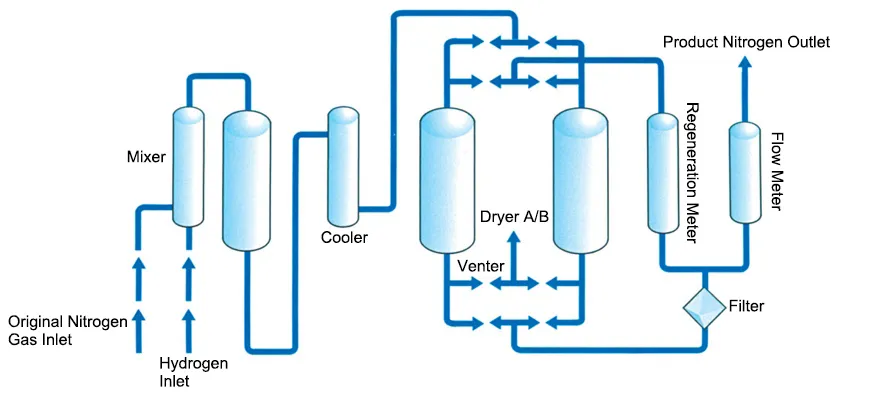

When nitrogen and hydrogen flow into the gas purification equipment and fully mixed, it enters the deoxidizer device and the chemical reaction of 2H2+O2=2H2O happens under catalyst. After deoxygenation, the nitrogen will enter the cooler to remove the moisture, then enters dryer A and dryer B to lower the dew point of the nitrogen gas to a degree lower than -60℃. When one dryer is undergoing the adsorption and drying process, the other will release the adsorbed moisture into atmosphere to make space for another adsorption process. After filtered to remove dust, the remaining gas will be the product, i.e. high purity nitrogen.

Want more information about gas generation equipment?

Contact us today and our experts are happy to advise you and find a solution to your application.

- Auxiliary Equipment

- Nitrogen Generators

- Oxygen Generators

-

Micro-Heat & Heatless Regeneration Adsorption Dryers

Working pressure: 0.6~1.0Mpa

Flow rate: 0.8-300Nm³/min

Pressure dew point: -20℃~-70℃ -

Air Compressor

Air compressor is essential in the preparation process of gas generation, it is used to compress, filter, dry and cool the ambient air.

-

PSA Oxygen Generator

Two adsorption tower will be installed in parallel in PSA oxygen generator, one tower begins the adsorption phase while other tower regenerates by de-pressurizing.

-

VPSA Oxygen Generator

Our VPSA oxygen generator is able to generate oxygen with purity between 90% and 95%. It is mainly composed of air blower, vacuum bump, switching valve and oxygen buffer tank.

-

Modular Oxygen Generator

Our modular oxygen generator has a compact structure, adopting non-pressure container molded in aluminum alloy die-casting and pipeline made of high strength alloy steel with quick-connect fittings.