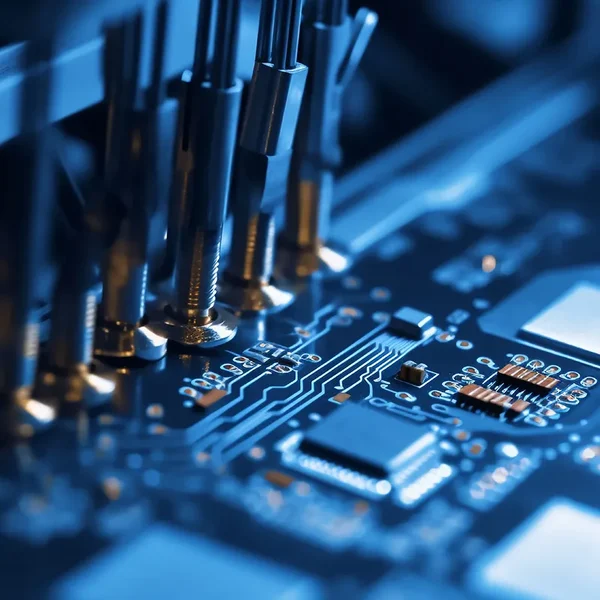

Since high purity nitrogen gas is required as carrier gas or protective gas in the production process of electronics, so that nitrogen generator is essential in the production of electronic components. Nitrogen can help prevent oxidation and corrosion of electronic components to effectively ensure the quality of final products. For example, in the welding process, nitrogen can reduce the oxygen molecules to protect the welding performance from being affected by oxygen molecules, as well as reducing the production of slag to reduce the difficulties and cost of cleaning.

The manufacture of semiconductor silicon also requires nitrogen as protective, cleaning and chemical recovery gas, in general, the nitrogen generator can effectively improve the quality, durability and productivity, as well as reduce costs in electronic industry.

With years of customization design experience, we can customize our nitrogen generators according to your specific needs for nitrogen delivery or welding. Until now, we have already developed long-term cooperation with many electronic manufacturers to empower their manufacturing. Our nitrogen generators can bring your process and manufacture to a new level, largely empowering your business.

- Customer Name: Wuxi Deke Li Optical Electronics Technology Co., Ltd.

- Equipment Model: RCN70-49

- Nitrogen Flow: 70 Nm³/h

- Purity: 99.99%

-

- PSA Nitrogen Generators PSA nitrogen generation is a technology to separate nitrogen from air by the adsorption ability of carbon molecular sieve under pressure by air compressor. After the air is compressed and purified (removing the oil, water and dust, etc.) before transferring into the absorption tower filled with carbon molecular sieves (CMS), the oxygen molecule will be adsorbed by carbon molecular sieve, while nitrogen molecules are too large so that they will not be adsorbed. Read More