PSA Nitrogen Generators

- Nitrogen capacity: 3-5000Nm³/h (standard conditions)

- Nitrogen purity: 90%-99.9995% (oxygen-free nitrogen)

- Nitrogen pressure: 0.1-0.8Mpa (stable and adjustable pressure)

- Nitrogen dew point: -40°C to -70°C (atmospheric pressure)

- Can be used in food freshness preservation in food processing plants, nitrogen needs in research laboratories, transport and storage of oil and gas, etc.;

- Can be used in nitrogen sealing, nitrogen protection, material transport and distribution in the production of the chemical and pharmaceutical industries, preventing oxygen contamination of raw materials and production processes;

- Can be used in lead-free reflow soldering, wave soldering, blowing and encapsulation, high-precision chip sealing, PCB baking and so on in electronic industry;

- Can be used in steelmaking converter sealing, steel annealing, vacuum quenching and other nitrogen-based atmosphere heat treatment in metallurgical heat treatment industry;

- Can be used as auxiliary gas in the laser cutting industry for cooling, as well as preventing oxidation

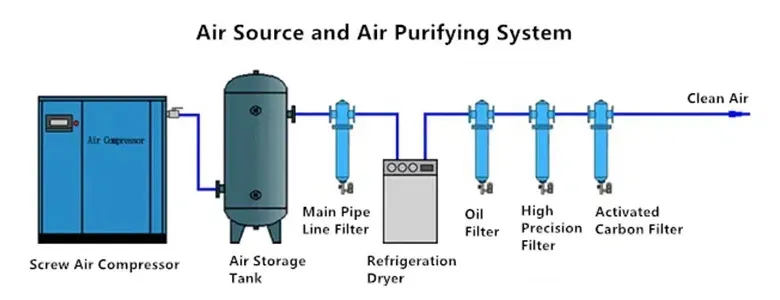

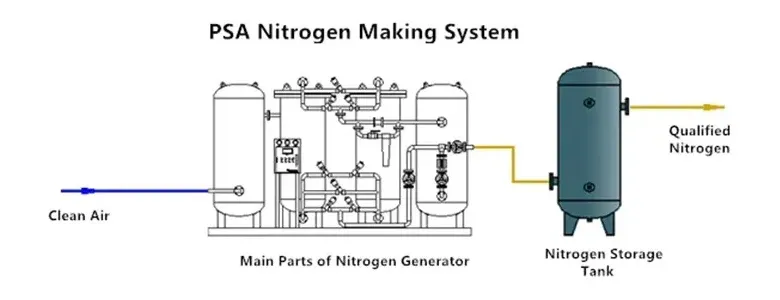

PSA nitrogen generation is a technology to separate nitrogen from air by the adsorption ability of carbon molecular sieve under pressure by air compressor. After the air is compressed and purified (removing the oil, water and dust, etc.) before transferring into the absorption tower filled with carbon molecular sieves (CMS), the oxygen molecule will be adsorbed by carbon molecular sieve, while nitrogen molecules are too large so that they will not be adsorbed. Those nitrogen molecules will pass through the tower into the nitrogen buffer tank, while oxygen molecules remain in the CMS. The adsorption process is performed at certain pressure, after that, the atmospheric pressure will be resumed again, and the adsorbed oxygen molecules will escape from CMS, passing the bottom of the tower through the exhaust silencing muffler into the air, and the CMS is available to be reused. Usually PSA nitrogen generator adopts double adsorption towers in parallel, they will be used alternatively for the adsorption and collection of the nitrogen under different pressure, continuously supporting the separation of oxygen and nitrogen and producing nitrogen. The above process will be automatically controlled by PLC system.

-

Cabinet PSA Nitrogen Generator

- Nitrogen capacity: 3-10Nm³/h

- Nitrogen purity: 95%-99.9%

Our cabinet PSA nitrogen generator can efficiently separate nitrogen with high purity. It not only occupies small space, but also protected by a metal case, preventing damage during operation. It is suitable for low-volume nitrogen generation, such as food preservation in small food processing manufacturers, nitrogen protection in scientific laboratories, etc. Our cabinet PSA nitrogen generators are designed for meeting different requirements across various industries, detailed specification and size can be customized upon customers’ request.

-

Twin Tower PSA Nitrogen Generator

- Nitrogen capacity: 20-5000Nm³/h (standard conditions)

- Nitrogen purity: 90%-99.999% (oxygen-free nitrogen)

- Nitrogen pressure: 0.1-0.8Mpa (stable and adjustable pressure)

- Nitrogen dew point: -40°C to -70°C (atmospheric pressure)

Our twin tower PSA nitrogen generator is available in different production specifications to meet various requirements. It is able to produce nitrogen with different purities ranging from 97%, 99.9%, 99.99%, to 99.999%. If your requirements still cannot be met, we can also customize the PSA nitrogen generator according to your needs. The flexibility and efficiency of our nitrogen generator makes it suitable for different industries, including but not limited to metallurgical heat treatment, oil and gas, chemical and pharmaceutical, food, lithium-ion battery, PV, electronics industries, etc.

-

Containerized PSA Nitrogen Generator

- Nitrogen capacity: 3-5000Nm³/h

- Nitrogen purity: 90-99.9995%

- Nitrogen pressure: 0.1-0.8Mpa (stable and adjustable pressure)

- Nitrogen dew point: -40°C to -70°C (atmospheric pressure)

Our containerized PSA nitrogen generator can separate nitrogen from compressed air utilizing pressure swing adsorption (PSA) technology, which is suitable for production of nitrogen in factories in bulk. All the components are setting inside containers so that the environmental requirement for the installation site is low, which makes it especially suitable for outdoor operations in harsh environment. We can also make customization design for equipment installation and specification according to your working environment and powering equipment to meet the need for different kinds of outdoor operation.