oxygen generators

Our PSA oxygen generator can separate oxygen from compressed air utilizing zeolite molecular sieve (ZMS) under pressurization. For PSA oxygen generator, the compressed air is first purified to remove the moisture, oil and dust. Then the purified air will pass through adsorption tower filled with ZMS. As nitrogen has a higher diffusion rate in ZMS pores, the sieve will adsorb the nitrogen and moisture over oxygen, allowing the oxygen to pass as product gas at pressure. After de-pressurizing, the sieve releases adsorbed gases into the atmosphere, and the process can then be repeated.

Two adsorption tower will be installed in parallel in PSA oxygen generator, one tower begins the adsorption phase while other tower regenerates by de-pressurizing. The PLC controller manages process valves with built-in logic for an automatic stop/start for continuous oxygen production. The whole system is composed of purification system for compressed air, air condenser, adsorption tower and oxygen buffer tank. PSA oxygen generation technology is widely used in industrial and medical applications for its efficiency, cost-effectiveness and low maintenance requirements.

- Oxygen capacity: 5-200Nm³/h

- Oxygen purity: 90%-94%

- Oxygen pressure: 0-0.5Mpa

- Oxygen dew point: -40℃ (atmospheric pressure)

- The compressed air will be purified first through the purification system, as clean and dry air can help prolong the service life of the molecular sieves

- Pneumatic valves support quick opening and closing without leakage, which makes this PSA oxygen generator satisfy the frequent usage of pressure swing adsorption (PSA) technology with long service life and high reliability

- Adopt the usage of latest molecular sieve, and complete process design for integrated and efficient production

- Adopt continuous systematic improvement and always equipped with latest production technology to save energy and lower the production cost

- Adopt compact design to reduce the space used for installation

- Use PLC control to ensure stable performance and automatic operation with low annual operation error rate

-

PSA Oxygen Generator

- Oxygen capacity: 5-200Nm³/h

- Oxygen purity: 90%-94%

- Oxygen pressure: 0-0.5Mpa

- Oxygen dew point: -40℃ (atmospheric pressure)

Two adsorption tower will be installed in parallel in PSA oxygen generator, one tower begins the adsorption phase while other tower regenerates by de-pressurizing. The PLC controller manages process valves with built-in logic for an automatic stop/start for continuous oxygen production. The whole system is composed of air purification system, air storage tank, separating system of nitrogen and oxygen, and oxygen buffer tank.

-

VPSA Oxygen Generator

- Oxygen capacity: 50Nm³/h-5000Nm³/h

- Oxygen purity: 50%-94%

Our VPSA oxygen generator is able to generate oxygen with purity between 90% and 95%. It is mainly composed of air blower, vacuum bump, switching valve and oxygen buffer tank. The production cost of using this VPSA oxygen generator will decrease as the production volume increases, which makes it suitable for applications like medium and large industrial systems where continuous supply of high purity oxygen is required. For this oxygen generator, we can delivery as turnkey project, as well as send professional technicians for on-site measurement, layout, preparation of drawings, and carry out equipment production and delivery after confirmation.

-

Modular Oxygen Generator

- Oxygen capacity: 1-30Nm³/h

- Oxygen purity: 93%+/-2%

Our modular oxygen generator has a compact structure, adopting non-pressure container molded in aluminum alloy die-casting and pipeline made of high strength alloy steel with quick-connect fittings. The installation process is convenient with no need for extra painting. Compared with traditional oxygen generator, it occupies less space, which makes it more suitable for application scenarios with high requirements for installation space, and related pressured containers report and inspection. Our modular oxygen generator can apply to various industries, including but not related to processed electronics, food, and workshops with high hygienic requirements.

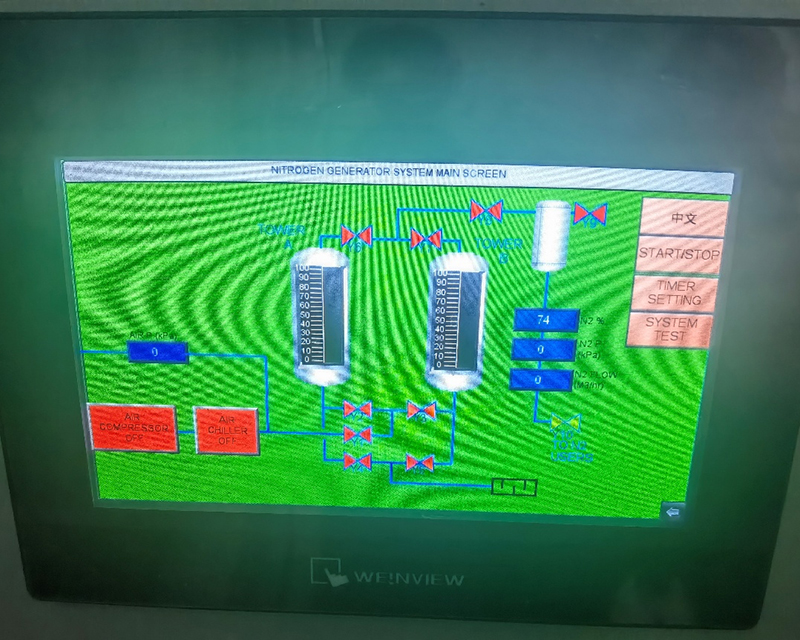

- Online monitoring of nitrogen purity, pressure, and flow.

- Human-machine interface (HMI) control system.

- Audible and visual alarms for off-spec nitrogen; automatic shutdown on prolonged alarm.

- Automatic reminder for vulnerable parts replacement.

- Automatic molecular sieve compaction.

- Pneumatic valve switching automatically controlled by programmable logic controller (PLC).

- Automatic drainage for refrigerated dryer and filters.

Molecular sieve compaction screen plate

Molecular sieve compaction screen plate-

Compaction device after molecular sieve filling

Compaction device after molecular sieve filling HMI (Human-machine interface) touch screen control

HMI (Human-machine interface) touch screen control

-

Controller online monitoring of purity, pressure, and other data

Controller online monitoring of purity, pressure, and other data Audible & visual alarm light (automatic alarm when purity/pressure falls below set value or a fault occurs)

Audible & visual alarm light (automatic alarm when purity/pressure falls below set value or a fault occurs)

- Automatic vent of off-spec nitrogen.

- Reserved RS485 communication port (Modbus or Profibus communication protocol) or Industrial Ethernet communication port.

- Industrial PC, printer, and intelligent IoT (Internet of Things) system.

The nitrogen generation system primarily consists of a compressed air purification unit, compressed air buffer unit, oxygen-nitrogen separation unit, nitrogen buffer unit, control unit, and nitrogen storage unit.